- 09 Jul, 2024

Tech stack in small and midsize factories

It's been four years since I started this blog with a simple but powerful idea: there's massive potential for improvement in the operations of small and medium-sized factories. Today, I want to revisit this topic, especially in light of the incredible technological developments we've seen globally—yet, somewhat ironically, many of our factories still rely heavily on good old spreadsheets for their ...

- 19 May, 2024

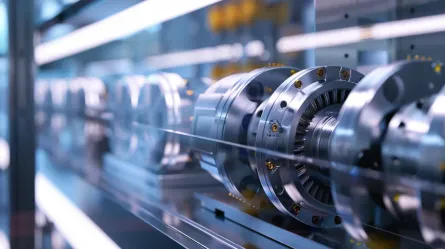

Image recognition in factories

Today, I'd like to chat about something that's been on my mind since I first stepped into the manufacturing world. Back then, the first thing I did was to make sure that every order leaving the factor ...

- 02 Jan, 2024

Increasing sales on high margin items

If you've ever been on the customer side of waiting days for a quote on standard spare parts, you know how frustrating it can be. It seems counterintuitive, right? In an age where almost everything is ...

- 25 Oct, 2023

Selection Software

I want to share a little story about my unexpected journey into the world of selection software, specifically the kind used in factories. It all started back in 2015. I was working in the quality depa ...

- 03 Aug, 2023

What is LK-99 and why it might be such a big deal

Today, I want to share some news that could revolutionize our field. Imagine a material that could make electric motors, batteries and electronics much cheaper. It might finally get us the flying cars ...