Data analysis for manufacturing components

- 26 Aug, 2021

It’s no secret data is key for your product. Big data has been in our mind for many years now, yet many companies struggle to extract meaningful information about the products they sell.

This is particularly true for configurable products like air handling units. Units can be as small as a shoe-box or as big as an entire 20-foot container. Imagination is the limit. There is a huge variety of components you can use in each ahu.

Having such big range of configurations, it’s difficult to get some insights about these products without doing some data analysis first.

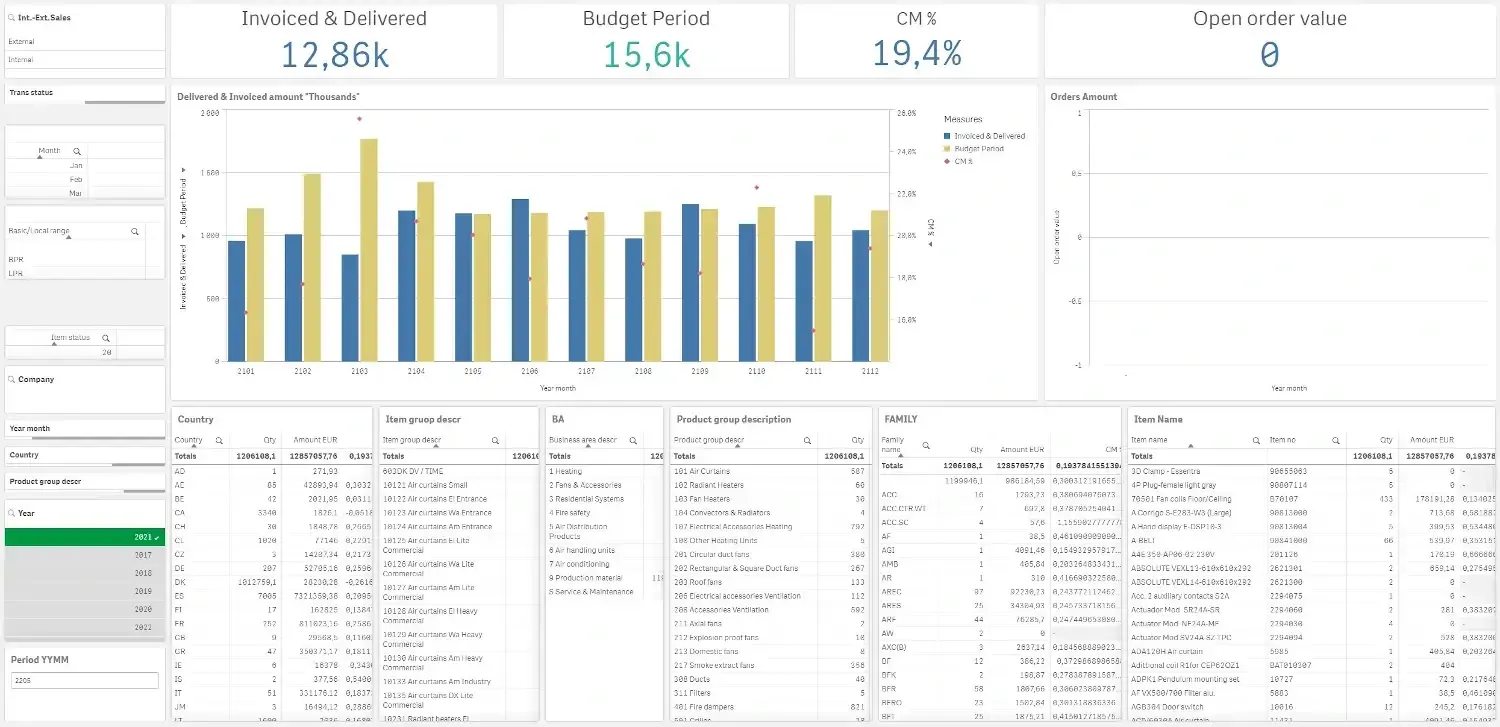

Sales reports

Companies use sales reports as one of their main key indicators. While this is correct for main operational job, there is much more one could do without much hassle. Main problem with these reports is that it only shows sales of particular items at high level (one car, three ships, two planes, etc.). There is no detail about components nor combination of them.

It’s not possible to know how many units have filters, or how many of them have coils. At such high item level there is no information to extract.

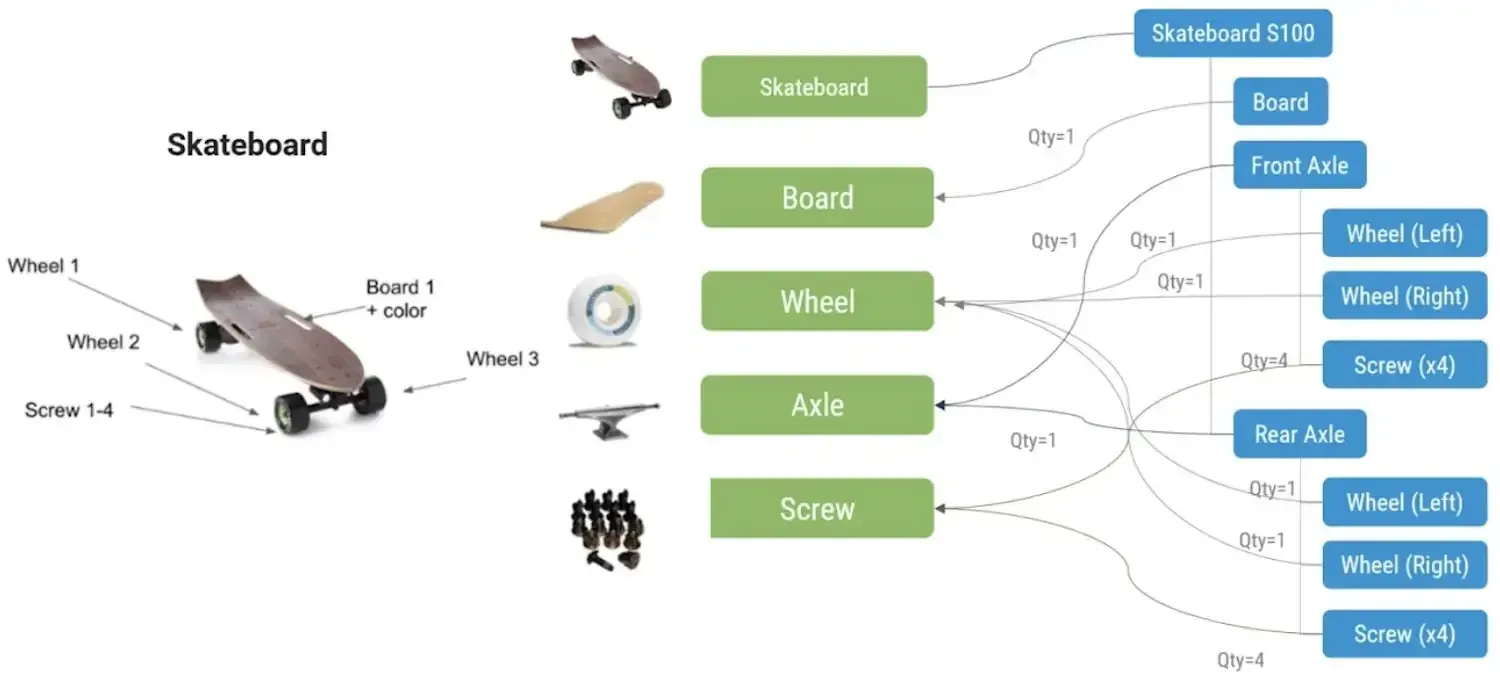

Bill Of Material (BOM)

Instead, we could use the bill of material of each item. ERP systems create a new manufacturing order for each unit, and then create all the needed orders to make the product.

Why is this useful?

Linking production and purchase information with sales is very important for several reasons: Interaction between components, profitability analysis of units by component level, client segmentation by used components, faster quotation for spares, etc.

All this can be done automatically with the data we already have in our ERP systems. No need to manual typing or human errors.